The material of the rubber strips for system windows determines their physical properties and service life. Under the condition that the material is qualified, its design becomes crucial. That is to say, it's about how to make good products with good materials. For example, just like the same dish made with the same ingredients, the differences can be quite significant when cooked by different chefs. This is something intrinsic. Professional people do professional work.

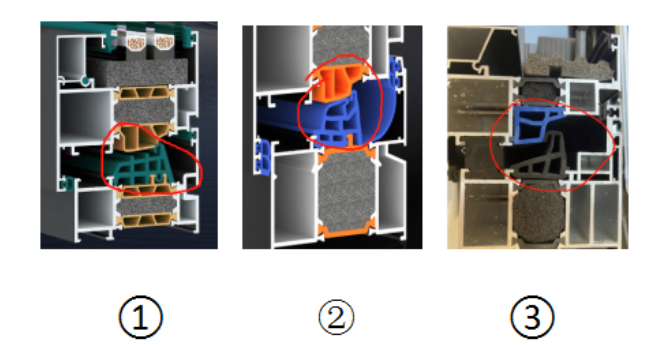

The following are the cross-sectional structure diagrams of three types of inward-opening windows, showing three typical designs of central equal-pressure rubber strips. The parts circled in red in the diagrams are the equal-pressure sealing rubber strips often mentioned in system windows.

①, ② and ③ are equal-pressure rubber strips with three different mouth shapes. In most terminal sales stores, the salespeople will tell you that the larger the overlapping amount is, the better, and the tighter the seal will be. In fact, this view is one-sided and isolated. Now, let's analyze the designs of the equal-pressure rubber strips in the three pictures below, and then you will understand what kind of rubber strip design is scientific and reasonable.

For the equal-pressure rubber strip in Picture ③, at the position where the rubber strip overlaps with the thermal break strip, the compression amount is not reasonable. That is to say, after the hardware is locked, there is still a large compression space between the rubber strip and the thermal break strip, which will form a weak point in the seal. In simple terms, it's a virtual connection. Moreover, the space between the thermal break strip and the equal-pressure rubber strip is too large, which will increase the heat convection at the opening part and affect the thermal insulation effect of the doors and windows.

For the design of the equal-pressure rubber strip in Picture ②, at first glance, the overlapping amount is large, and the gap between the rubber strip and the thermal break strip is completely filled by the surface of the rubber strip, which seems quite solid. However, such a rubber strip design ignores one problem. That is, at the position of surface contact, after repeated opening and closing, the surface of the rubber strip will be worn out, which will affect its service life. There may be after-sales problems later. Besides, such a mouth shape design will increase the opening and closing force of the opening sash, making it not very convenient to use.

For the equal-pressure rubber strip in Picture ① designed by E-Taifeng, the overlapping part between the rubber strip and the thermal break strip adopts a folded-overlap design. When designing, the rubber content of the rubber strip, the compression amount and the overall effect after the hardware is locked are all taken into consideration. The overlapping amount and the reserved compression amount are both reasonable. In the gap between the thermal break strip and the rubber strip, by using two small protrusions on the rubber strip, on the premise of ensuring the opening and closing force of the opening sash, the heat convection is minimized to ensure the thermal insulation effect of the doors and windows. This is a scientific, reasonable and systematic rubber strip design.

The above comparative analysis, which is about the advantages and disadvantages of different mouth shape designs of equal-pressure rubber strips, is hoped to be helpful to you when you choose windows.