On January 7th, the Etaifeng factory hosted a visiting team of clients from Spain. This visit was not a simple tour, but a deep exchange focused on Aluminum exterior casement window products, past collaborations, and future plans.

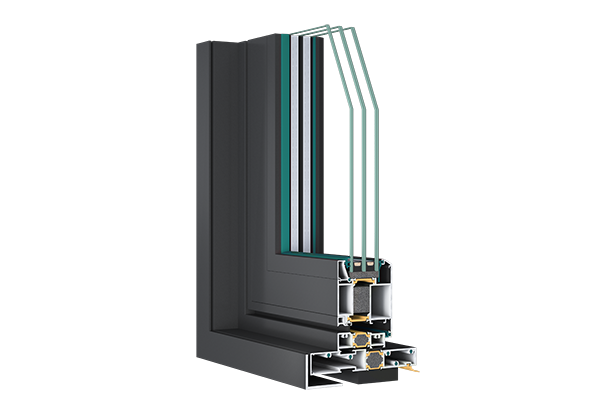

Upon arriving at the Etaifeng factory, the clients immediately went to the Aluminum exterior casement window production workshop. Compared to brochures and pictures, the clients were more interested in seeing the actual production site and understanding the entire process of manufacturing a system window, from profile processing to finished product. We guided the clients through the core processes, including profile cutting, corner assembly, hardware installation, glass assembly, and finished product testing. System windows require high precision and specific assembly sequences, and many details can only be truly understood on-site, which was the most important aspect of the visit for the clients.

During the visit, the clients showed great interest in Etaifeng's streamlined production line management and workstation division of labor, especially inquiring in detail about hardware installation, sealing treatment, and multiple quality inspection stages. We also explained, based on our production experience, why we invest more man-hours and testing resources in these stages, because the ultimate stability, sealing performance, and service life of Aluminum exterior casement windows largely depend on these details.

After the production line tour, both parties engaged in a more in-depth discussion, focusing on reviewing the previous collaborative project. The entire process was thoroughly reviewed, from order confirmation and technical parameter communication to production pace, delivery arrangements, and end-user installation feedback. The clients candidly shared their experiences with the Aluminum exterior casement window products in their local projects in Spain and also suggested areas for improvement in communication and delivery processes.

For Etaifeng, this feedback is invaluable. We don't shy away from problems; instead, we hope to clarify what was done well and what can be improved through this review. Both parties also redefined clearer and more efficient communication processes on-site, focusing on details such as drawing confirmation, parameter modification feedback, and progress synchronization, with the sole goal of making future collaborations smoother and reducing unnecessary repeated confirmations.

In the latter part of the discussion, the clients introduced their overall plan for the 2026 system window project, including product positioning, market demand, and expectations for supply stability. We also shared our long-term plans for Aluminum exterior casement window manufacturing, based on Etaifeng's current production capacity, production line configuration, and continuous improvement efforts.

After a full day of discussions, both sides reached a consensus: truly valuable cooperation must be built on a foundation of mutual understanding and trust. Through factory visits, project reviews, process optimization, and future planning, this visit from the Spanish client team not only deepened their understanding of Etaifeng's manufacturing capabilities but also increased both parties' confidence in future cooperation. We look forward to using more such face-to-face, in-depth communication methods to foster long-lasting partnerships with each of our clients in the future.